Elevators are important means of transportation in mid to high rise buildings. With the rapid development of China's economy and society, the aging population is becoming increasingly severe. The annual production and ownership of elevators have rapidly increased, and the presence or absence of elevators has become an important factor in evaluating people's quality of life. As an organic component of buildings, the energy consumption of elevators is also an important performance indicator in building energy consumption. In response to China's new requirements for energy conservation and emission reduction, reducing the huge energy consumption of elevators has become an important indicator pursued by the elevator industry. The guide shoe is the guiding device of the elevator that directly contacts the working plane of the guide rail, so there will be significant friction loss during the transportation of passengers and goods in the elevator. Therefore, analyzing the factors that affect the friction between the guide shoe and the guide rail has great engineering value in reducing friction and consumption.

1. The role of guiding boots

Guide shoes are devices used to prevent the elevator car and counterweight from tilting during up and down operation, ensuring smooth elevator operation. The guide shoes are installed on the car and counterweight device. The car guide shoes are installed on the upper beam of the car and under the safety clamp seat at the bottom of the car. There are a total of four sets of counterweight guide shoes installed on the upper and bottom of the counterweight frame. The concave groove (or roller) of the guide shoe cooperates with the convex working surface of the guide rail during work, so that the car and counterweight device only move up and down along the working surface of the guide rail, preventing the car and counterweight device from tilting or swinging during operation.

2. Classification and Structure of Guide Shoes (Guide Shoes in Elevator Guidance Systems)

Guide shoes can be divided into sliding guide shoes and roller guide shoes according to their different motion modes with the working surface of the guide rail. Sliding guide shoes are divided into fixed sliding guide shoes and elastic sliding guide shoes according to whether the axial position of the boot head is adjustable. The fixed sliding guide shoe (see Figure 1 for appearance) is mainly composed of a shoe lining and a shoe seat, also known as a rigid sliding guide shoe. Due to the large gap between the shoe lining of the fixed guide shoe and the top and two sides of the guide rail, which is generally about 0.5-10mm, it will generate significant vibration and impact during movement. Therefore, it is usually used for elevators with a speed of 1m/s or less that do not require high operating quality. Due to its simple structure, high stiffness, and strong load-bearing capacity, it is widely used in low-speed and large tonnage freight elevators.

The elastic sliding guide shoe is composed of a boot seat, boot head, boot lining, boot shaft, compression spring or rubber spring adjusting sleeve or adjusting nut, and is further divided into unidirectional floating spring type (see structure in Figure 2) and rubber spring type sliding guide shoe (see structure in Figure 3). For unidirectional floating spring type sliding guide shoes, they can provide cushioning in the direction perpendicular to the top surface of the guide rail, but there still needs to be a large gap between them and the working surfaces on both sides of the guide rail, which makes them have no buffering effect on the vibration and impact on the working surfaces on both sides of the guide rail. Therefore, the rated speed of elevators using this structure guide shoe is generally limited to 1.75m/s. Rubber spring type elastic sliding guide shoes have a certain directionality at the shoe head, so the cushioning performance on the working surfaces on both sides of the guide rail is also improved, and the applicable elevator speed range is correspondingly increased.

Rolling guide shoes, also known as roller guide shoes (appearance figure 4), are composed of rollers, springs, and shoe seat rocker arms. Due to the use of rolling contact, the roller guide shoes can reduce the frictional resistance between the guide shoes and the guide rails, reduce vibration and noise, and are commonly used in high-speed elevators.

3. The main factors affecting the friction of guide shoes

The friction between elevator guide shoes and guide rails is a dynamic and complex process with multiple coupled factors, which are influenced by various factors such as shoe lining material, lubrication state, relative velocity of contact load, and surface roughness.

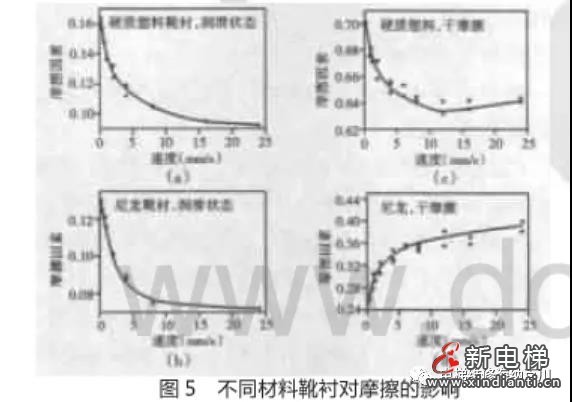

(1) Shoe lining material. The lining material of sliding guide shoes is generally wear-resistant nylon hard plastic, fiberglass cast iron or other polymer materials. Ni Ting also compared the friction performance of nylon glass fiber reinforced polytetrafluoroethylene and ultra-high molecular weight polyethylene materials under four sliding conditions in his paper. By comparing data under different materials, it can be known that different shoe lining materials have different friction characteristics.

(2) Lubrication status. Under lubricated conditions, a layer of oil film will form between the guide rail and the boot liner to separate them, converting dry friction into wet friction and greatly reducing the friction coefficient and friction. Generally speaking, the frictional force under lubrication conditions is much smaller than that under dry friction. Therefore, sliding guide shoes generally need to be lubricated with oil to reduce friction.

(3) Contact pressure. The contact pressure between the guide shoe and the guide rail surface mainly comes from the balance reaction force generated by the bias of the car load. The normal pressure on the guide shoe can sometimes reach over 1000. The sensitivity of different materials to contact loads varies due to friction. Generally speaking, the friction coefficient decreases with the increase of normal pressure. Although the friction coefficient decreases, the overall friction force increases due to the increase in pressure.

(4) Operating speed. Under certain pressure conditions, wear will increase with the increase of speed, reach a certain maximum value, and then decrease with the increase of sliding speed.

(5) Surface roughness. Under the same load conditions, the rougher the surface, the greater the frictional force and the more severe the wear. Under each load, there is a most reasonable surface roughness at which the wear is minimal. If the wear exceeds this roughness, it will increase again. This is because the surface roughness is too small, which increases the contact area and enhances the intermolecular attraction. Lubricants cannot be stored in the friction surface and are prone to adhesion and frictional biting.

Daily maintenance of guide shoes

The guide shoe is an important device for maintaining the smooth operation of the elevator. Whether the guide shoe works normally will directly affect the noise, comfort, smoothness, and leveling error of the elevator. Therefore, it is necessary to do a good job in the daily maintenance of the guide shoes.

Elevators are special equipment. According to the Chinese special equipment safety technical specification TSG/T5001-2009 "Elevator Use Management and Maintenance Rules", the basic requirements for the maintenance of the oil cup on the guide shoe are to check that the oil absorbing felt is complete, the oil volume is appropriate, and the oil cup is leak free. The basic requirement for the maintenance of shoe lining and rollers in item 7 of the quarterly maintenance project and requirements is that the amount of cleaning and wear should not exceed the requirements of the manufacturing unit. As a professional elevator maintenance personnel, it is far from enough to meet these basic maintenance requirements. A responsible enterprise should strictly control every link from the procurement of components, installation of elevators to subsequent maintenance, ensuring the mechanical properties such as strength, hardness, and wear resistance of shoe lining materials, ensuring the processing quality of elevator guide rail working surfaces, ensuring the straightness of guide rails during elevator installation, ensuring the parallelism of two rows of guide rails to the plumb line, ensuring the spacing and rigidity of guide rail installation brackets, and repairing the gaps at guide rail joints. The maintenance and inspection of sliding guide shoes after the elevator is put into operation should start from the following aspects.

(1) The gap between the side lining of the car guide shoe and the guide rail is 0.5-1mm. The elastic sliding guide shoe lining has no gap with the top surface of the guide rail, and the adjustment range of the guide shoe spring does not exceed the standard. The gap between the fixed sliding guide shoe lining and the top surface of the guide rail is 1-2mm. The gap between the lining of the counterweight guide shoe and the top surface of the guide rail shall not exceed 2.5mm

(2) Check the upper guide shoes and counterweight guide shoes of the elevator car. Standing at the top of the elevator car, the elevator car and counterweight maintenance run in a suitable horizontal position for inspection. Swinging the elevator car or counterweight frame back and forth can check the size of the side clearance and top clearance, as well as the wear of the shoe lining. It can also check the spring force of the spring. Check the lower guide shoes of the elevator car: The maintenance personnel should stand in the pit and move the elevator car to the lowest suitable maintenance position, and check the condition of the guide shoes by shaking the elevator car back, forth, left, and right. If the top clearance is too large, the boot liner can be removed and a shim can be added to its top surface for adjustment. If the side clearance is too large for the embedded shoe lining, the side clearance can be adjusted by adjusting the bolt of the side shoe lining. The integral boot lining can be adjusted by adding shims on the back side of the boot lining to make the gap slightly larger on one side. The best way to achieve unsatisfactory results after adjustment is to replace the boot lining with a new one.

(3) Keep the guide rail clean and lubricated, and promptly remove dirt from the guide rail surface and boot lining. Due to the up and down movement of the elevator car, it will drive the flow of air and the flying of sand and dust in the shaft. These dust particles are easily adsorbed on the working surface of the guide rail, causing serious wear and tear on the boot and guide rail. Therefore, the working surface of the sliding guide rail should be cleaned according to regulations to ensure the normal operation of the guide rail, reduce friction noise during operation, and improve the service life of the boot lining.

(4) Severe wear and tear of the boot lining, foreign objects getting stuck, excessive clearance, or skewed installation can cause rail gnawing during the operation of the elevator car. When conducting routine maintenance, it is found that there are small and bright scratches on the side of the guide rail, and in severe cases, there are burrs on the scratches. The wear of the shoe lining on the side is uneven and there are burrs. When the car deviates and twists during starting and leveling, it can be basically judged that rail gnawing has occurred. There are many reasons for rail gnawing, mainly due to twisted or loose installation of the guide rails, misalignment of the upper and lower guide shoes, and inconsistent clearance with the guide rails. The car frame is deformed or the shoe seat bolts are loose. The outer dimensions of the shoe lining are too small and shake inside the shoe head. At this point, adjustments should be made based on the specific reasons to eliminate rail gnawing and replace the boot lining.

5. Conclusion

The lining of the sliding guide shoe, whether made of iron, nylon, or hard plastic, always has friction between the lining and the guide rail during elevator operation. This frictional force not only increases the load on the traction machine but also is one of the causes of car vibration and noise during operation. In order to reduce the friction between the guide shoe and the guide rail, save energy, improve ride comfort, and enhance the induction of the guide shoe, daily inspection, maintenance, cleaning, lubrication, adjustment, and timely replacement of the shoe lining can be carried out. If necessary, the roller guide shoe can be replaced.